What is Custom Cotton Fabric?

Custom cotton fabric refers to textile products made from natural cotton fibers that undergo personalized processing, including material selection, weaving methods, printing, and finishing, to meet specific design or functional requirements. Unlike mass-produced cotton fabrics, custom cotton fabrics allow clients to participate in the production process, choosing parameters such as fiber type, weave structure, color, and pattern according to their needs, thereby achieving unique product performance or aesthetic effects. This flexible production model makes cotton, a traditional natural fiber, shine in modern personalized consumption scenarios, whether it is high-end fashion, brand promotional products, or home textiles, all can find suitable custom solutions.

Cotton fabric itself is made from the fluffy fibers surrounding the seeds of the cotton plant. These cellulose-based fibers have inherent characteristics such as breathability, softness, and high absorbency, which lay a good foundation for customization. During the production process, after harvesting and ginning, cotton fibers are spun into yarns, and then woven or knitted into fabrics through different processes. Common weave methods include plain weave, twill weave, and satin weave, each of which gives the fabric different textures and strengths. For example, plain weave cotton is lightweight and soft, suitable for making shirts and dresses; twill weave forms diagonal lines, making the fabric more durable, which is the preferred material for work clothes and jeans; satin weave has a smooth and glossy surface, often used in high-end bedding.

The History and Evolution of Custom Cotton Fabric

The history of cotton fabric can be traced back to around 5000 BCE in the Indus Valley, where people first spun cotton fibers into yarn and woven them into fabric. Over time, cotton cultivation and processing techniques spread to ancient Egypt, China, and the Americas. The Mayans and Aztecs in the Americas, as well as ancient Egyptians and Indians in Africa and Asia, all developed unique cotton textile cultures. However, the real leap in cotton production came during the Industrial Revolution. The invention of Eli Whitney's cotton gin in 1793 mechanized the separation of cotton fibers from seeds, greatly improving production efficiency and laying the foundation for large-scale cotton fabric production.

In the 20th century, with the development of chemical industry and textile technology, cotton fabric production entered a new era. The emergence of blended fabrics (such as cotton-polyester blends) expanded the application range of cotton fabrics, but also made consumers pay more attention to the natural attributes of cotton. In recent years, with the rise of personalized consumption and environmental awareness, custom cotton fabric has become a new trend. Brands and consumers are no longer satisfied with mass-produced products, but pursue unique designs and sustainable production methods. This shift has promoted the integration of traditional cotton textile technology with modern digital technology, such as digital printing and intelligent production lines, making small-batch and multi-variety customization possible.

Types of Cotton Fabric for Customization

The diversity of cotton fabrics provides rich choices for customization. Here are some common types

- Muslin: A lightweight plain-weave cotton fabric with good breathability, often used for making summer clothing, curtains, and as a base fabric for printing customization

- Percale: A closely woven plain-weave fabric with a smooth texture and crisp feel, suitable for high-end bed sheets and pillowcases. Customization can focus on thread count and dyeing processes to improve comfort and aesthetics.

- Twill: Characterized by diagonal rib patterns, twill fabrics are durable and have a distinct texture. They are widely used in workwear, jeans, and jackets. Custom options include adjusting the density of the twill and adding stretch fibers

- Sateen: Made with a satin weave, sateen has a glossy surface and a smooth hand feel, making it ideal for luxury bedding and dressy clothing. Customization can focus on luster enhancement and anti-wrinkle treatments.

- Denim: A sturdy cotton twill fabric with a distinctive diagonal weave, denim is the classic material for jeans. Customization includes washing processes, color fading effects, and embroidery designs.

- Flannel: A soft, slightly napped cotton fabric that provides warmth, flannel is commonly used in shirts and pajamas. Customization can adjust the napping degree and pattern printing to meet different warmth and style needs.

- Jersey: A knit cotton fabric known for its stretch and comfort, jersey is widely used in t-shirts and casual wear. Custom options include adding spandex to adjust elasticity and digital printing for personalized patterns.

- Canvas: A heavy-duty plain-weave cotton fabric with high strength and durability, canvas is suitable for making bags, tents, and upholstery. Customization can involve thickness adjustment, waterproof treatments, and logo printing.

The Custom Cotton Fabric Production Process

The production of custom cotton fabric is a systematic project that involves multiple links from raw material selection to finished product delivery. Here is a detailed breakdown of the process:

1. Raw Material Selection

The first step in customization is choosing the right cotton fiber. Common options include conventional cotton, organic cotton, Egyptian cotton, Pima cotton, etc. Organic cotton, grown without synthetic pesticides and fertilizers, is favored by environmentally conscious brands and consumers. GOTS-certified organic cotton ensures that the entire production process meets strict environmental and social standards. For high-end customization, long-staple cotton such as Egyptian cotton or Pima cotton is often chosen for its softer and more durable fibers.

2. Fiber Processing and Spinning

After selecting the cotton fibers, they undergo processes such as cleaning, carding, and spinning to form yarns. The thickness and twist of the yarn can be customized according to needs. For example, 40s yarn is suitable for lightweight fabrics, while 30s yarn is used for thicker fabrics. Compacted and combed yarns can improve the smoothness and strength of the fabric, which is an important option for high-quality custom fabrics.

3. Weaving or Knitting

The yarns are then woven or knitted into fabrics using different techniques. Weaving methods include plain weave, twill weave, and satin weave, while knitting methods include single jersey and double jersey. The choice of weave or knit method directly affects the texture, elasticity, and appearance of the fabric. For example, canvas uses a plain weave for high strength, while jersey uses a knitting method for stretchiness.

4. Dyeing and Printing

Dyeing and printing are key links in realizing personalized designs. Custom cotton fabric can use various dyeing techniques, such as reactive dyeing, pigment dyeing, etc. Reactive dyeing has good color fastness and is suitable for bright colors. Printing methods include screen printing, digital printing, heat transfer printing, etc. Screen printing is suitable for large batches and bold designs, while digital printing allows for complex patterns and small-batch customization with high precision. Heat transfer printing is suitable for personalized logo printing on cotton tote bags.

5. Finishing Treatments

Finishing treatments improve the performance and appearance of the fabric. Common finishing processes include mercerizing, which increases the luster and strength of the fabric; anti-shrinking treatment, which ensures the stability of the fabric size; and anti-static treatment, which is suitable for workwear fabrics. For custom home textiles, wrinkle-resistant and stain-resistant finishes can also be added according to needs.

6. Quality Control and Testing

Each batch of custom cotton fabric needs to undergo strict quality control, including testing for color fastness, strength, shrinkage, and environmental indicators. Professional QC teams conduct inspections throughout the production process to ensure that the finished product meets customer requirements. For example, some manufacturers have more than 20 quality inspectors responsible for different production links.

Applications of Custom Cotton Fabric

Custom cotton fabric is widely used in various fields due to its flexibility and personalization. Here are some typical application scenarios:

1. Apparel Industry

In the apparel industry, custom cotton fabric is used to create unique clothing styles. Fashion brands can customize fabrics according to seasonal themes, such as printing floral patterns on lightweight cotton voile for summer dresses, or using twill cotton with custom dyeing for autumn jackets. For workwear, OEM manufacturers can produce cotton-polyester blended fabrics with anti-static and wear-resistant properties according to corporate needs. Baby clothing often uses custom organic cotton jersey fabrics, which are soft and hypoallergenic, ensuring the safety and comfort of infants.

2. Promotional Products and Branding

Custom cotton tote bags are one of the most popular promotional products. Businesses can print their logos or slogans on cotton canvas tote bags to enhance brand awareness. These tote bags are not only practical but also environmentally friendly, in line with the concept of sustainable development. Custom options include bag size, handle length, printing position, etc. Some manufacturers even provide digital mockups for customers to confirm before production.

3. Home Textiles

Custom cotton fabrics add personality and comfort to home life. In home textiles, custom options include printed bed sheets, embroidered tablecloths, and patterned curtains. For example, percale cotton with custom patterns can be used to make bed sheets that match the bedroom decor, while canvas cotton can be customized into durable cushion covers. Some brands offer monogram embroidery services, adding a unique touch to napkins and tablecloths.

4. Industrial and Special Applications

In industrial fields, custom cotton fabrics are used to produce workwear, tarps, tents, etc. For example, heavy-duty canvas can be customized into waterproof tarps for outdoor use, while cotton fabrics with anti-static and flame-retardant treatments are suitable for workwear in special industries. In medical textiles, custom cotton gauze and bandages with high absorbency and hypoallergenic properties are widely used.

Sustainable Development of Custom Cotton Fabric

With the increasing awareness of environmental protection, sustainable customization has become an important trend in the cotton fabric industry. Organic cotton, as a sustainable raw material, is widely used in custom production. Organic cotton is grown without synthetic pesticides and fertilizers, reducing environmental pollution and protecting the health of farmers. GOTS (Global Organic Textile Standard) certification ensures that organic cotton fabrics meet strict environmental and social criteria throughout the production process, from cultivation to processing.

In addition to using organic raw materials, sustainable customization also involves optimizing production processes. For example, adopting water-saving dyeing technologies and using eco-friendly dyes reduce the environmental impact of production. Some manufacturers even offer undyed organic cotton fabrics, which retain the natural color of cotton fibers and avoid the pollution caused by dyeing processes.

Custom cotton fabric also contributes to reducing waste. Through precise order quantity control and small-batch production, it avoids overproduction and inventory accumulation. Reusable custom cotton tote bags replace disposable plastic bags, helping to reduce plastic pollution and promote a circular economy.

About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric printing enterprise integrating product R&D, design, production, and sales. It provides a full range of fabric printing and assembly products, including hats, flags, T-shirts, umbrellas, towels, etc.

With 31 years of production experience, Gahumi's products have been exported to regions such as Africa (including Ghana), the United States, Europe, and the Middle East, and it is familiar with the multi-category customization needs of large-scale official activities. The company has more than 300 professional employees and 3 production bases with a total area of 5,000 square meters (including a raw material center, a fully automatic printing center, a sewing center, and an assembly center). It can flexibly allocate multi-line production resources and provide OEM/ODM services to efficiently meet the needs of million-level multi-category order.

.webp)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

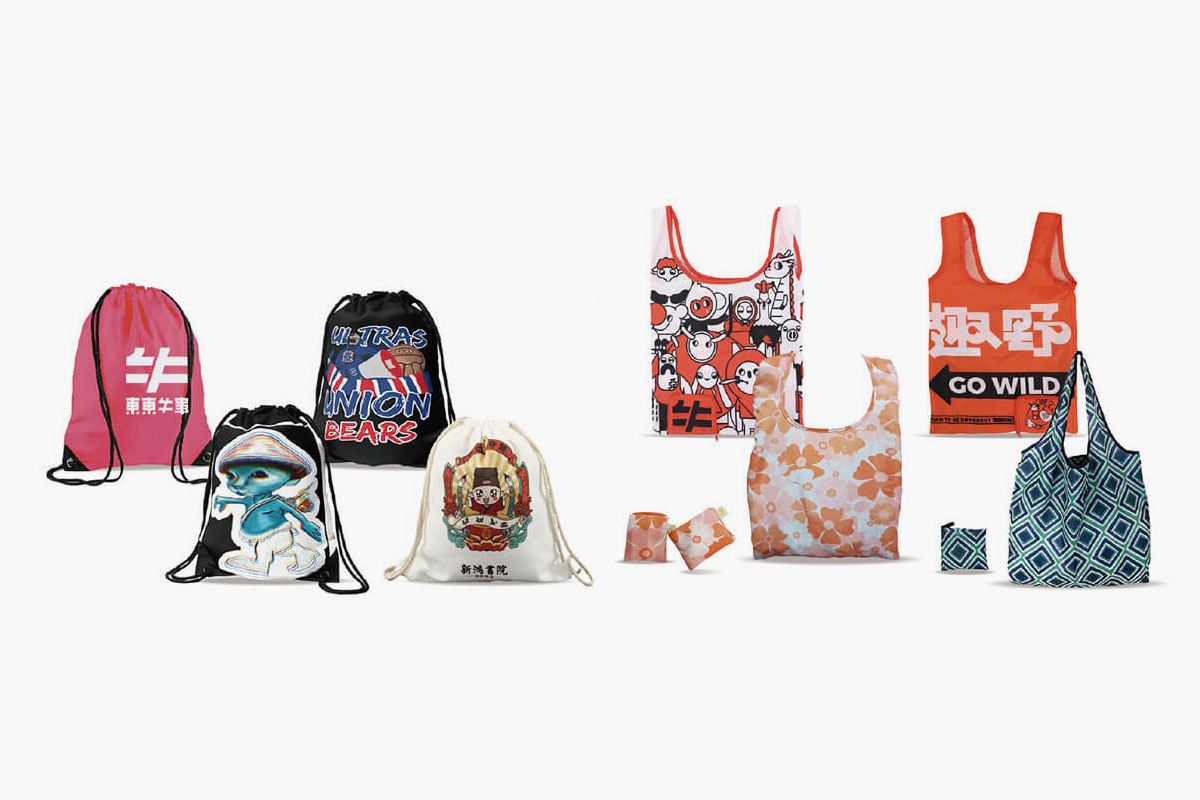

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap

.webp)