Custom Bag Fabric & Polyester Bag Guide

When embarking on designing or customizing an exclusive bag, the choice of fabric is a core factor that determines its final quality and user experience. Among various options, cost-effective custom polyester bags have become a top choice for numerous enterprises and individuals, thanks to their versatile application scenarios and mature manufacturing processes.

Dec 01, 2025

Views:

142

|

Gahumi

When embarking on designing or customizing an exclusive bag, the choice of fabric is a core factor that determines its final quality and user experience. Among various options, cost-effective custom polyester bags have become a top choice for numerous enterprises and individuals, thanks to their versatile application scenarios and mature manufacturing processes. Whether it's bulk-customized polyester promotional bags for corporate marketing, wear-resistant custom polyester organizing bags for daily storage, or waterproof custom polyester sports bags for outdoor leisure, polyester fabric consistently adapts to diverse needs with its stable performance. This article will focus on the application scenarios and manufacturing characteristics of polyester bags, and provide comprehensive customization references through a comparison with nylon.

In-depth Analysis: Core Value of Polyester Bags – Scenario Adaptability and Craft Support

As a synthetic material derived from petrochemicals, polyester owes its excellent wrinkle-resistant and shrink-resistant properties to the stability of its molecular structure. Meanwhile, mature manufacturing processes further amplify these advantages. From daily consumption to commercial promotion, and from leisure scenarios to special needs, the application scope ofcustom polyester bags continues to expand, supported by both its scenario adaptability and craft reliability.

Diversified Application Scenarios of Polyester Bags: Comprehensive Coverage from Daily Life to Business

The cost-effectiveness and stability of polyester fabric enable it to demonstrate outstanding advantages in various scenarios, making it an "all-rounder" in the custom bag field.

1. Business Promotion and Corporate Gift Scenarios: Perfect Balance Between Cost and Effect

It has become a mainstream choice for enterprises to customize polyester promotional tote bags and brand logo custom polyester backpacks for exhibitions and promotional activities. The core demands for bags in such scenarios are "low cost, high exposure, and easy dissemination" – requirements that polyester perfectly meets. Its raw material cost is 20%-30% lower than that of nylon, offering significant unit price advantages for bulk customization. Additionally, polyester boasts extremely strong color stability; corporate logos and promotional slogans printed via screen printing or heat transfer will not fade easily even after exposure to sun and rain, allowing the bags to continuously convey brand information during daily use by consumers. For instance, takeaway complimentary bags from catering chains and exhibition gifts from technology companies mostly adopt polyester fabric, which not only controls marketing costs but also ensures a consistent brand image.

2. Daily Commuting and Home Storage Scenarios: Dual Guarantee of Practicality and Durability

For ordinary consumers, polyester commuting backpacks, foldable custom polyester shopping bags, and polyester clothing storage bags are "practical essentials" in life. In commuting scenarios, bags need to hold laptops, documents, and other items – the stiffness of polyester prevents the bag from deforming, and its wrinkle-resistant property eliminates the need for frequent maintenance. In shopping scenarios, foldable polyester bags are lightweight and portable, with large capacity when unfolded, and can be reused, aligning with environmental protection needs. For home storage, waterproof custom polyester storage boxes can isolate moisture, protecting clothes, quilts, and other items from dampness and mildew, making them particularly suitable for use in humid southern regions.

3. Casual Sports and Light Outdoor Scenarios: Precise Adaptation of Waterproof and Breathable Properties

In sports and light outdoor scenarios, polyester sports gym bags and lightweight custom polyester hiking bags are highly favored. Polyester has excellent moisture-wicking capabilities, reducing stuffiness and stickiness when storing sweaty sportswear. Polyester fabric treated with PU coating also features high waterproof performance, easily coping with sudden light rain or sweat penetration during sports. Although polyester is slightly heavier than nylon, this difference is almost negligible in light scenarios such as short-distance hiking, morning runs, and fitness. Moreover, its lower price makes it more accessible to consumers.

4. Special Needs and Industry-Specific Scenarios: Customized Choices for Functional Adaptation

After being processed with different techniques, polyester can also meet the needs of specific industries. For example, polyester medical storage bags, after waterproof coating treatment, are easy to clean and disinfect, making them suitable for storing medical equipment or first-aid supplies.Polyester school bags for students adopt twisted polyester fabric, which is wear-resistant and durable, capable of withstanding long-term pressure from books without deformation. Portable custom polyester pet bags utilize the fabric's soft and scratch-resistant properties to provide a comfortable and safe travel space for pets.

Manufacturing Characteristics of Polyester Bags: Stable, Efficient, and Easy to Customize

The widespread application of polyester bags is inseparable from the maturity and flexibility of their manufacturing processes. Every step, from fabric pre-treatment to forming and sewing, is designed around the fabric's properties, ensuring both quality and customization efficiency.

1. Fabric Pre-treatment Process: Enhancing Properties and Improving Adaptability

Before cutting, polyester fabric usually undergoes pre-treatment processes such as "preshrinking, shaping, and coating". The preshrinking process uses high-temperature steam to eliminate internal stress in the fabric, preventing shrinkage and deformation of the finished bag after washing or dampening. The shaping process maintains the stiffness of the fabric, ensuring a neat bag shape. Coating treatment tailored to different needs is particularly crucial: waterproof coatings (such as PU coating) enhance the fabric's water-repellent performance, making it suitable for outdoor bags or storage bags; antistatic coatings are used in custom polyester storage bags for electronic accessories to prevent electrostatic damage to equipment. These pre-treatment processes make the properties of polyester fabric more in line with scenario requirements.

2. Cutting and Sewing Processes: Adapting to Fabric Properties and Ensuring Durability

Polyester fabric has high strength and is not easily torn, so automated cutting beds can be used for precise cutting, ensuring consistent sizes especially for bulk customization. In terms of sewing processes, "double-thread overlocking + reinforced stitching" is usually adopted. For stress-bearing parts of the bag, such as shoulder straps, handles, and the bottom, additional polyester webbing is used for reinforcement to improve load-bearing capacity. For example, the connection between the handle and the body of a custom polyester tote bag undergoes 3-4 rounds of stitching and is fixed with metal rivets, ensuring it can bear a weight of over 10 kilograms to meet daily shopping needs. Compared with nylon fabric, the wear resistance of polyester makes the sewing stitches more stable, avoiding the problem of thread wear and breakage.

3. Printing and Customization Processes: Vibrant Colors and Durable Patterns

Personalization is one of the core demands for custom bags, and polyester stands out with its advantages in printing processes. Due to the stable molecular structure of the fabric and strong dye adsorption capacity, it is perfectly compatible with processes such as screen printing, heat transfer, and digital printing. Screen printing is suitable for bulk customization of simple logos, featuring low cost and high efficiency. Heat transfer can present complex patterns and gradient colors, making it suitable for trendy custom polyester personalized bags. Digital printing supports small-batch personalized customization, meeting the needs of individuals or niche brands. Crucially, the printed patterns on polyester have high color fastness, maintaining bright colors even after more than 50 washes – an advantage that nylon fabric can hardly match.

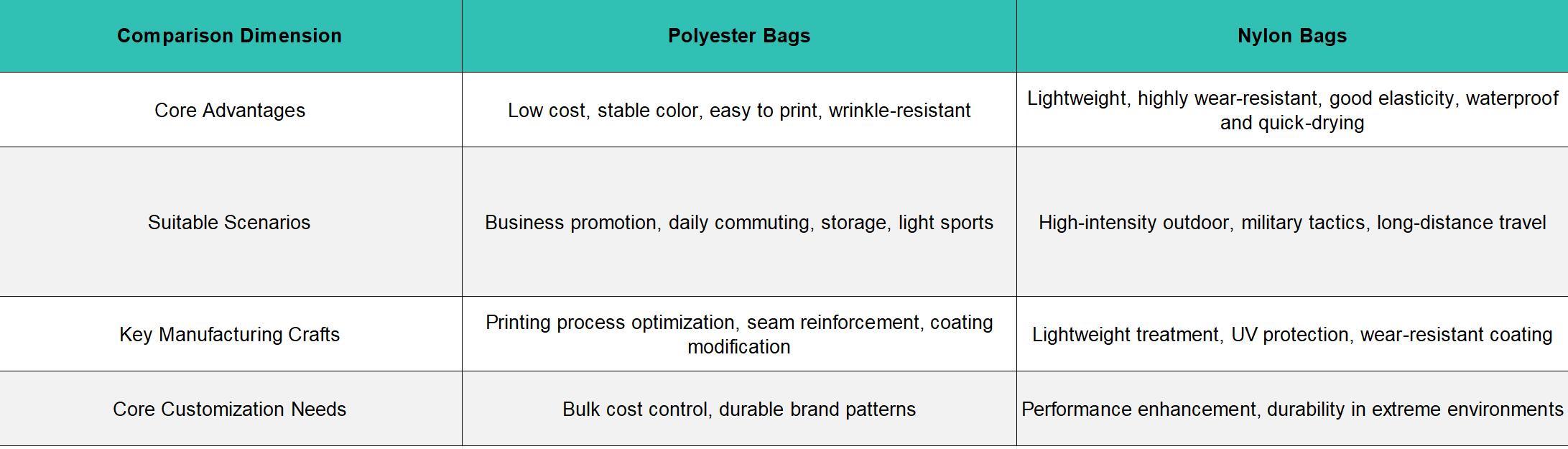

Scenario & Craft Comparison Between Polyester and Nylon Bags: Make Accurate Choices Without Mistakes

Although polyester bags have a wide range of applications, nylon remains a better choice in some scenarios. A comparison of scenarios and crafts can help you accurately match your needs.

Nylon vs Polyester: Performance Comparison Table

| Performance Metric | Nylon | Polyester |

|---|---|---|

| Tensile Strength | ★★★★★ (Very High) | ★★★★☆ |

| Abrasion Resistance | ★★★★☆ | ★★★★★ (Superior) |

| Water Absorption | 3–4% | <1% |

| Drying Speed | Slow | Fast |

| UV Resistance | Medium (Weakens Over Time) | Excellent (Color-Stable) |

| Coating Adhesion | Strong (Ideal for TPU/PU) | Good |

| Cost Level | Higher | Lower |

| Texture | Softer, premium, flexible | Stiffer to mid-soft, depends on denier |

| Best Bag Types | Outdoor, tactical, heavy-duty | Everyday, gym, travel, promo bags |

For example, when customizing high-altitude hiking backpacks that need to cope with strong UV rays and scratches from sharp rocks, nylon's high wear resistance and UV protection technology are more suitable. When customizing campus recruitment promotional bags, the focus is on enabling students to obtain practical bags at a low price and spread recruitment information – in this case, polyester's printing advantages and cost advantages are more prominent.

Custom Polyester Bag Guide: Craft Selection and Scenario Matching Skills

When customizing polyester bags, it is necessary to select appropriate fabric specifications and manufacturing processes based on usage scenarios to maximize their value.

1. Select Fabric Specifications by Scenario: Precise Matching of Grammage and Density

The grammage (g/㎡) and density of polyester fabric directly affect the performance of the bag. For lightweight commuting bags, choose thin fabrics with 120-180 g/㎡ for portability. For load-bearing storage bags, thick fabrics with 200-300 g/㎡ are required to ensure strength. Foroutdoor sports bags, it is recommended to choose fabrics with a density of ≥300T, paired with waterproof coating to improve durability.

2. Select Crafts by Demand: Customization from Printing to Structure

For commercial customization, prioritize screen printing to reduce bulk costs. For personalized customization, digital printing can be selected to achieve exclusive patterns. For outdoor scenarios, additional waterproof coating and reinforced stitching are needed. For electronic storage bags, antistatic coating should be added. For example, when customizing corporate annual meeting gift bags, the process of "thick polyester + screen-printed logo + reinforced handle" can be adopted to balance texture and practicality.

3. Avoid Customization Mistakes: Focus on Details to Improve User Experience

Some customizers only focus on price and patterns, ignoring craft details. It should be noted that the inner side of the bag is recommended to be lined with polyester to improve texture and protect items. Choose metal or nylon zippers to avoid breakage caused by friction with polyester fabric. Shoulder straps can adopt the combination of "polyester webbing + sponge padding" to improve load-bearing comfort.

Custom Polyester Bag FAQ: Answers to 6 Most Concerned Questions

Q1: Are custom polyester bags suitable for long-term outdoor exposure?

A1: Absolutely. Polyester has much higher UV resistance than nylon. Its molecular structure can resist UV erosion, and it is not prone to fabric aging, embrittlement, or fading even after long-term outdoor exposure. It is an ideal choice for custom outdoor camping equipment bags and beach storage bags. For further enhancement, fabrics with additional UV protection coating can be selected.

Q2: What is the most cost-effective minimum order quantity (MOQ) for bulk customization of polyester promotional bags?

A2: Generally, the cost advantage of polyester bag customization is most obvious when the MOQ is ≥500 units. At this quantity, factories can uniformly carry out fabric cutting, printing, and sewing, sharing fixed costs. If the order quantity is less than 100 units, digital printing is recommended. Although the unit price is slightly higher, it avoids fabric waste and is more suitable for small-batch needs.

Q3: Do polyester bags pill easily? How to maintain them?

A3: High-quality polyester bags are not prone to pilling. Pilling usually occurs due to loose fibers on the fabric surface, which can be avoided by choosing fabrics with a density of ≥200T. For maintenance, polyester bags can be machine-washed (water temperature ≤30℃) with mild detergent, and should not be washed with sharp objects. After drying, if there is slight lint, it can be cleaned with a lint roller, requiring no special care.

Q4: How long can the waterproof effect of customized waterproof polyester bags last?

A4: It depends on the waterproof process. Ordinary PU-coated waterproof bags can maintain their waterproof effect for 1-2 years under daily use. High-end models with PTFE coating (Teflon) can maintain waterproof performance for 3-5 years. To extend the waterproof life, avoid frequent rubbing of the waterproof coating and let the bag air-dry naturally after cleaning.

Q5: Can polyester bags be customized into vacuum storage bags?

A5: Yes. Thick polyester fabric (≥250 g/㎡) should be selected, paired with PEVA composite layer technology to enhance airtightness and pressure resistance. Such custom polyester vacuum storage bags are more wear-resistant than ordinary plastic storage bags, can be reused, and are suitable for storing bulky items such as down jackets and quilts.

Q6: What are the advantages of polyester-cotton blended bags compared to pure polyester bags?

A6: Polyester-cotton blended bags (usually with a ratio of 7:3 or 6:4) combine the wrinkle-resistant and wear-resistant advantages of polyester with the breathable and skin-friendly properties of cotton, making them suitable for making custom polyester storage bags for intimate clothing and baby product bags. However, the cost of blended fabrics is 10%-15% higher than that of pure polyester, and their color stability is slightly worse, so a trade-off should be made based on the scenario.

Waterproof Performance: A Key Consideration for Custom Bags

Whether for outdoor travel or daily use, bags may be exposed to rain and moisture, so waterproof performance is crucial. Nylon itself has good water-repellent ability – raindrops are not easy to penetrate its surface, and it dries quickly after getting wet. With waterproof coating treatment, it can be made into highly waterproof custom outdoor bags to easily cope with humid environments. Polyester also has excellent waterproof performance and outstanding moisture-wicking ability; even if wet clothes are stored inside, it can reduce stuffiness, making it suitable as custom sports backpacks or custom storage bags for bathroom use. In addition, nylon has mildew-resistant properties, making it more resistant to mildew growth than polyester in humid southern regions or rainforest expeditions.

Cost and Customization Flexibility: Polyester Offers Better Cost-effectiveness

Cost is an important consideration for corporate customization and bulk customization. Under the same specifications, the raw material cost of polyester is 20%-30% lower than that of nylon, which gives bulk-customized polyester promotional bags significant unit price advantages – very suitable for enterprises to carry out promotional activities and giveaways. In terms of customization flexibility, nylon has better dyeing performance, capable of presenting brighter colors and diverse textures, making it suitable for high-end custom trendy bags that pursue personalized design. Polyester, on the other hand, excels in color stability; printed patterns will not fade easily after sun exposure and washing, making it an ideal choice for custom brand logo bags.

UV Resistance and Application Scenarios: Polyester is More Sun-resistant

For custom bags used outdoors for a long time, UV resistance of the fabric must be considered. The molecular structure of polyester has stronger resistance to UV rays; even under long-term exposure to strong sunlight, it is not prone to fabric aging and embrittlement, making it suitable as custom outdoor camping equipment bags and custom beach storage bags. Nylon has relatively weak UV resistance; long-term exposure may lead to reduced strength and faded colors. Therefore, when using nylon bags outdoors, it is recommended to choose custom nylon bags with UV protection treatment or match them with sunshades.

Scenario-based Buying Guide: Optimal Fabric Choices for Different Needs

Combined with the above performance differences, custom bags for different scenarios have varying fabric requirements. The following provides clear fabric selection suggestions for common custom scenarios to help you avoid mistakes.

Outdoor Exploration and Military Use: Nylon Fabric is the First Choice

If your customization needs are for high-intensity custom outdoor hiking bags or custom tactical training backpacks, nylon is undoubtedly the best choice. In such scenarios, bags need to withstand multiple tests such as heavy object extrusion, branch scratches, and rain soaking. Nylon's high wear resistance, stretch resistance, waterproof and quick-drying properties can perfectly cope with these challenges. For example, tactical bags in the military field almost all use nylon fabric to ensure reliability in complex environments.

Corporate Promotion and Promotional Activities: Polyester is More Cost-effective

When enterprises customize a large number of custom promotional bags and custom exhibition gift tote bags, cost and consistent appearance are core demands. Polyester not only has a lower unit price but also offers stable color and good printing effects, capable of clearly presenting corporate logos and promotional information. Even after multiple uses, the patterns remain bright. At the same time, its good durability allows the bags to circulate for a long time, extending the promotional effect – making it the most cost-effective choice.

Daily Commuting and Fashion Matching: Flexible Choices Based on Style

For custom daily commuting backpacks and custom fashion shoulder bags, fabric selection can be based on personal style and usage habits. Consumers pursuing a lightweight and smooth texture can choose nylon fabric – its silky touch and diverse colors can create a simple and high-end style. Those who prefer a solid and matte texture are more suitable for polyester models – its slightly rough texture can add a retro charm to the bag. If you often encounter rain during commuting, both fabrics can be selected with waterproof treatment.

Customization for Special Scenarios: Don't Overlook Other High-quality Fabrics

In addition to nylon and polyester, other high-quality fabrics can also be considered for custom bags in some special scenarios. For example, custom retro-style tote bags are suitable for canvas fabric – the texture of natural fibers can highlight the retro atmosphere. Custom medical-specific bags can choose vinyl fabric with PVC or PU coating – its waterproof and easy-to-clean properties meet the hygiene requirements of medical scenarios. Custom protective cases for electronic products are suitable for neoprene (diving material) – its soft texture can effectively buffer impacts and protect equipment safety.

Custom Bag Buying FAQ: Answers to 6 Most Concerned Questions

Q1: How much more expensive arecustom nylon bags than polyester bags? Is it worth buying?

A1: Under the same specifications, the price of custom nylon bags is usually 20%-30% higher than that of polyester bags. Whether it is worth buying depends on the usage scenario. For scenarios with high performance requirements such as outdoor and military use, the durability and reliability of nylon far exceed the price difference, making it very worthwhile. For daily light use or bulk promotion, polyester offers better cost-effectiveness.

Q2: Do custom polyester bags pill easily? How to maintain them?

A2: Polyester itself is not prone to pilling, but if there are loose fibers on the fabric surface, slight pilling may occur after long-term friction. For maintenance, avoid friction with sharp objects. Choose mild detergent when cleaning, with water temperature not exceeding 30℃. Gently comb the surface after drying. Most custom polyester bags can be machine-washed, making maintenance very convenient.

Q3: Can highly waterproof custom nylon bags be directly soaked in water?

A3: Although nylon has good waterproof performance, nylon bags with ordinary waterproof treatment can only resist rain washing and splashing, and cannot be directly soaked in water. If soaking scenarios need to be coped with, professional waterproof custom nylon bags treated with professional waterproof coatings (such as PU coating and PTFE coating) should be selected. The seams of such bags are usually sealed with glue, allowing short-term soaking.

Q4: When customizing logo custom bags in bulk, which has better printing effect – nylon or polyester?

A4: Both are suitable for printing, but each has its own advantages. Polyester has strong color stability, and printed patterns are not easy to fade, making it suitable for complex logos and multi-color printing. Nylon has good dyeing performance, capable of achieving brighter backgrounds, and can create high-saturation visual effects with screen printing. Specifically, the appropriate printing process can be selected through communication with the custom manufacturer based on logo design and color requirements.

Q5: What parameters should be paid attention to when choosing nylon fabric forcustom outdoor backpacks?

A5: The core parameter to focus on is "Denier (D)", which is an important indicator of nylon strength. The higher the denier, the thicker and more wear-resistant the fabric. For daily outdoor use, 420D-840D nylon is sufficient. For high-intensity hiking and tactical scenarios, it is recommended to choose nylon with a denier of ≥1000D, such as 1000D Cordura nylon, which offers better strength and durability. At the same time, it is necessary to confirm whether the fabric has undergone waterproof and UV protection treatments.

Q6: Can the advantages of nylon and polyester be combined in custom bag fabrics?

A6: Yes. Some high-end custom bags adopt "blending" or "zoned material use" to combine the advantages of both fabrics. For example, nylon is used in the bottom and corners of the bag that are prone to wear to improve durability, while polyester is used in the main body to control costs and ensure color stability. This design not only meets the performance requirements of key parts but also takes into account cost-effectiveness, making it suitable for customization needs that require both quality and cost control.

Additional SEO-related Elements

SEO Title: Nylon vs. Polyester Custom Bags: Which Fabric Suits Your Needs? - 2025 Buying Guide

Keywords: Custom Bag Fabrics, Custom Nylon Bags, Custom Polyester Bags, Custom Backpacks, Logo Custom Bags

Description: Choosing between nylon and polyester for custom bags? This article compares the core differences in durability, weight, and waterproof performance of the two fabrics, provides buying suggestions combined with scenarios such as high-intensity custom outdoor hiking bags and cost-effective custom promotional tote bags, and includes 6 common FAQs to help you choose the right custom bag fabric.

share

Contact Us

Your email address will not be published. Required fields are marked*

Related Products

.webp)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap