Brand Story

Cross-Border E-Commerce Storage Solution Provider

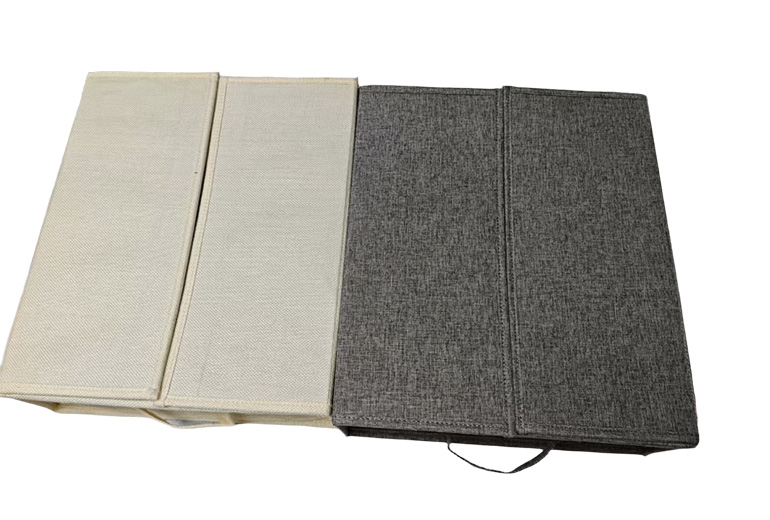

The client is a cross-border e-commerce enterprise focusing on home storage products. It is committed to providing practical and aesthetically pleasing storage products for global consumers, among which sheet storage boxes are one of its core best-selling products. Its products take "space optimization and convenient storage" as the core selling points and are sold well in European and American markets. The client attaches great importance to product quality and delivery efficiency and needs to rely on reliable OEM factories for large-scale production to meet the stable supply demand of overseas markets. The 72,000-unit sheet storage box order this time is for stock preparation to cope with the overseas shopping peak season.

Brand Goals

Ensure the on-time delivery of 72,000 sheet storage boxes to meet the inventory demand for sales during the overseas peak season and avoid the impact of stockouts on store sales and user reputation.

Ensure that products meet weight standards to control transportation costs, while guaranteeing the quality of fabrics, accessories and sewing craftsmanship to improve consumers' using experience.

Seek long-term and stable OEM partners to achieve the stable production of 10,000 units per month and support the long-term competitiveness of products in the cross-border market.

Solutions

Efficient Customization + Accurate Delivery

In response to the client's needs, Gahumi has developed a full-process customized solution. Facing the need for customized materials, it connected with high-quality suppliers in advance, promoted the customization of fabrics and accessories simultaneously, and accurately matched the production schedule to avoid delays. In view of the characteristics of multiple production processes, it optimized the production process, clarified the time nodes of each link, and ensured the stable production capacity of 10,000 units per month.

In the quality control and testing links, to balance the hardness, support force and weight of accessories, 8 prototype tests were conducted repeatedly, and the optimal solution was finally found to avoid increased transportation costs due to overweight. In the sewing link, senior workers were arranged for operation, and the whole process was supervised to ensure that the products were not deformed. In the packaging stage, the special requirements of "single unit in a plastic bag, 4 or 6 units in a large plastic bag, and different sets in a carton" were strictly implemented. At the same time, strict self-inspection was carried out throughout the whole process to ensure that the products met the standards. Finally, the production was completed ahead of schedule and waited for the client's shipment instruction.

🚩About the Customer

The client is a cross-border e-commerce company deeply engaged in the home storage field. Its product range covers sheet storage boxes, clothing storage boxes and other categories, and its products are mainly sold to European and American countries through platforms such as Amazon and eBay. It has won the favor of overseas consumers with "high cost-effectiveness and practical design", with an annual sales volume of over 10 million yuan. It has high requirements for the production capacity, quality control standards and delivery efficiency of OEM factories. This cooperation with Gahumi is an important measure for it to expand production capacity and consolidate its market position.

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric-printing enterprise integrated with product R&D, design, manufacture and sales. We offer a full line of fabric-printing products, including towels, golf towels, flags, advertising T-shirts, sports items, fans’ scarves, hats & caps, and other election accessories, etc.

Based on 31 years of manufacturing experience, we have been exporting products to the US, Europe, East Asia, Africa, and the Middle East, and have established long-term partnerships with companies around the world.

With over 300 highly qualified employees and 3 manufacturing facilities covering a total area of 5,000 square meters (including a raw material center, sewing center, fully automatic printing center, and assembling center), our clients benefit from lower manufacturing costs and timely mass production for market launch.

👏Case Summary

The project’s success lies in efficient response and process collaboration—rapid quotation locked the demand, 1-round sampling reduced iterations, and multi-process parallel production shortened the cycle. Delivering within 12 days confirms Gahumi’s cost control and execution capabilities in FMCG promotion customization.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

Cooperating with Gahumi on the 72,000-unit sheet storage box project has completely exceeded our expectations. Every link, from the 8 prototype tests to accurately find the material balance point to the early completion of production waiting for shipment, reflects professionalism and efficiency. The efficient implementation of special packaging requirements and the stable production capacity of 10,000 units per month have also laid a foundation for our future cooperation. Gahumi is a trustworthy OEM partner in our cross-border business.

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap