Brand Story

A Certain Group is a large-scale enterprise focusing on the R&D and sales of industrial equipment and supporting tools. With "high quality and high durability" as its core brand concept, it serves customers in fields such as manufacturing and engineering construction. The customized tool bags this time are used for equipment matching and on-site staff work, requiring properties like water resistance, wear resistance, and structural stability. Meanwhile, they need to pass ROHS certification to ensure environmental compliance, imposing strict requirements on material customization, process precision, and delivery efficiency to match the professional image and usage scenario needs of its industrial-grade products.

Brand Goals

Complete the customization of 5,000 tool bags within 30 days and deliver in advance to meet the customer’s on-site inspection needs; meet requirements such as water resistance, ROHS certification, and logo weather resistance through material customization and 3 sampling tests; ensure product durability with special sewing techniques; and strengthen the stability and professionalism of the group’s tool-supporting supply chain with compliant qualifications and meticulous quality control.

Solutions

Dual Guarantee of Material Customization + Exquisite Workmanship & Compliance

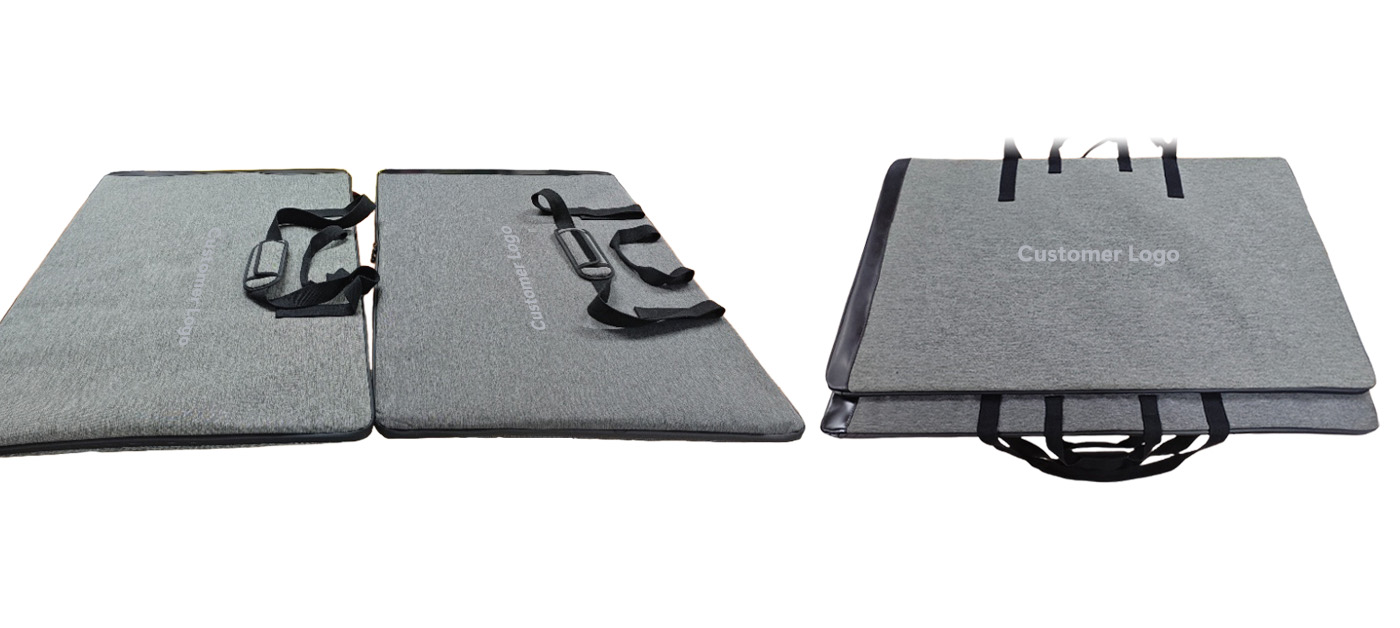

To meet the needs of fabric, lining, and webbing customization as well as certification, Gahumi quickly selected high-quality suppliers for emergency material procurement and simultaneously conducted secondary inspection and screening to ensure water resistance performance met standards and ROHS certification was obtained. For the 5MM splints and special TPU corner protectors, manufacturers with certification qualifications were prioritized to shorten the material preparation cycle and reserve sufficient time for production.

To address the challenges of complex sewing and special equipment requirements, Gahumi deployed dedicated sewing equipment and arranged senior technicians to operate in accordance with standardized processes. It focused on controlling the splicing of TPU corner protectors and the fixing of splints to avoid product deformation. For the special logo treatment, 3 sampling tests were conducted, and finally, the alcohol test and dry rub test were passed to ensure weather resistance. At the same time, an exclusive production area was planned to meet site requirements, and aiming at the heavy weight of the products, the packing plan was optimized to balance the number of products per box and transportation efficiency.

🚩About the Customer

A Certain Group has been deeply engaged in the industrial field for many years, with its business covering equipment manufacturing, tool supporting, and other sectors. It serves corporate customers in many parts of the world and builds a supply chain system with strict quality standards and compliance requirements. The customization of tool bags this time is an important measure to improve its equipment supporting services and enhance the efficiency of on-site staff. It has extremely high screening standards for the material customization capabilities, certification compliance, and production response speed of cooperative factories.

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric-printing enterprise integrated with product R&D, design, manufacture and sales. We offer a full line of fabric-printing products, including towels, golf towels, flags, advertising T-shirts, sports items, fans’ scarves, hats & caps, and other election accessories, etc.

Based on 31 years of manufacturing experience, we have been exporting products to the US, Europe, East Asia, Africa, and the Middle East, and have established long-term partnerships with companies around the world.

With over 300 highly qualified employees and 3 manufacturing facilities covering a total area of 5,000 square meters (including a raw material center, sewing center, fully automatic printing center, and assembling center), our clients benefit from lower manufacturing costs and timely mass production for market launch.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

Within the tight 30-day cycle, Gahumi perfectly solved the problems of tool bag material customization, multiple certifications, and complex sewing. Not only did it deliver 1 day ahead of schedule, but all 5,000 products also passed the on-site inspection. The 3 sampling tests accurately met requirements like water resistance and ROHS certification, and we have great trust in its professional production capabilities.

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap