Brand Story

JiujiBiology is a well-known enterprise focusing on the big health industry, adhering to the brand concept of “Empowering Health with Technology, Conveying Care through Quality”. Its business covers the R&D, production and sales of health products. This customization of scarves and canvas bags is intended to be used as brand peripherals for customer rewards, business gifts and offline event scenarios. These products not only need to reflect the brand’s high-end tone but also ensure practicality and texture. Therefore, extremely high standards are set for the production precision, craftsmanship level and delivery efficiency of cooperative factories to match its professional brand image in the health industry.

Brand Goals

Complete the customized production of 6,000 scarves and 6,000 canvas bags within 30 days, ensure quality through full inspection, help JiujiBiology improve the material layout for customer rewards and business scenarios with high-quality products that align with the brand tone, and strengthen the cooperative trust between the two parties with compliant qualifications and efficient delivery.

Solutions

Multi-Category Collaboration + Exquisite Craftsmanship to Ensure Delivery

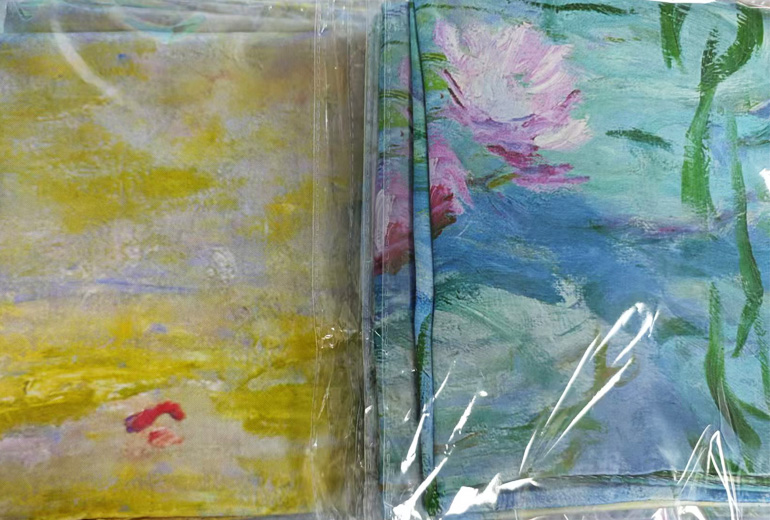

To tackle the high craftsmanship difficulty and strict requirements for fabrics and printing, Gahumi established a cross-category special team to handle the production of scarves and canvas bags separately. For the scarf segment, it strictly selected high-count fabric suppliers, optimized the printing process to ensure accurate colors, and arranged dedicated personnel to package scarves with gloves and protect them with interlayer white cardboards to avoid scratches. For the canvas bag segment, special positioning jigs were used to solve the problem of dimensional deviation in the peripheral embroidery of woven label logos on irregularly shaped canvas bags. For the high-difficulty sewing of double-layer handle tank bags, senior technicians were deployed to operate in accordance with standardized processes to ensure sewing quality and efficiency.

Solutions

To meet the needs of multiple auxiliary materials and different processes, Gahumi quickly selected suitable auxiliary material suppliers, customized exclusive materials and advanced sampling tests simultaneously, and passed core requirements such as woven label logos after 2 sampling tests. At the same time, it efficiently organized complete qualification documents and followed up on the full inspection of products throughout the process to ensure all 12,000 products met quality standards and were finally delivered on time.

🚩About the Customer

JiujiBiology has been deeply engaged in the big health industry for many years, with technological innovation as its core driving force. It is committed to providing high-quality health products and services for consumers and has a good brand reputation in the industry. It attaches great importance to brand image building and has strict control over the quality, design and texture of peripheral materials in scenarios such as customer rewards and business cooperation. This customization of scarves and canvas bags is an important measure to improve its brand scenario material system.

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric-printing enterprise integrated with product R&D, design, manufacture and sales. We offer a full line of fabric-printing products, including towels, golf towels, flags, advertising T-shirts, sports items, fans’ scarves, hats & caps, and other election accessories, etc.

Based on 31 years of manufacturing experience, we have been exporting products to the US, Europe, East Asia, Africa, and the Middle East, and have established long-term partnerships with companies around the world.

With over 300 highly qualified employees and 3 manufacturing facilities covering a total area of 5,000 square meters (including a raw material center, sewing center, fully automatic printing center, and assembling center), our clients benefit from lower manufacturing costs and timely mass production for market launch.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

Within the tight 30-day cycle, Gahumi perfectly addressed the challenges of ‘complex craftsmanship and high requirements’ for scarves and canvas bags. All 12,000 products were delivered on time and passed the full inspection. The 2 sampling tests accurately solved the positioning problem of woven label logos. Its professional production capacity and compliant qualifications made the preparation of our brand peripheral materials very reassuring.

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap