Brand Story

This batch of foldable shopping bags was coordinated by Guangzhou Chuangrui International Trade Co., Ltd. for supply to the Korean market. As daily necessities with both practicality and brand communication value, the Korean market has strict standards for product appearance precision, material texture, and cost control. Customized production is required to meet differentiated demands.

Brand Goals

The demand side in the Korean market aimed to enhance brand exposure in terminal scenarios through customized foldable shopping bags. It required the products to meet high standards in color reproduction and craftsmanship texture, while controlling costs and ensuring delivery within 1 month to align with the market launch schedule.

Challenges Faced

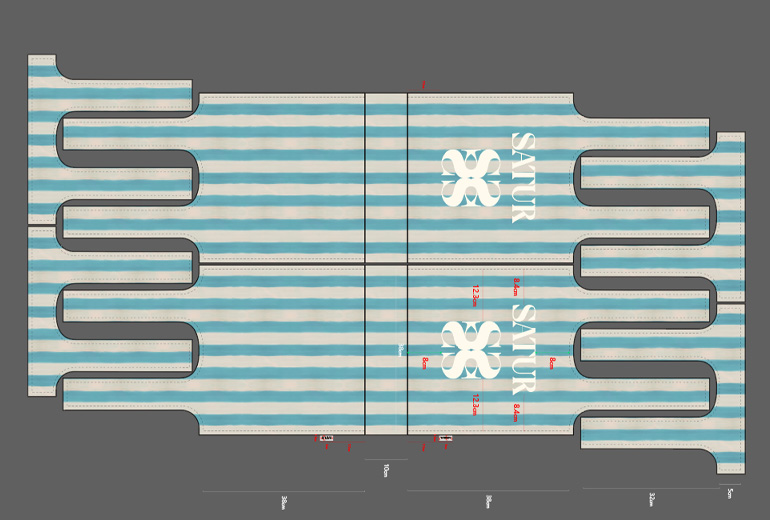

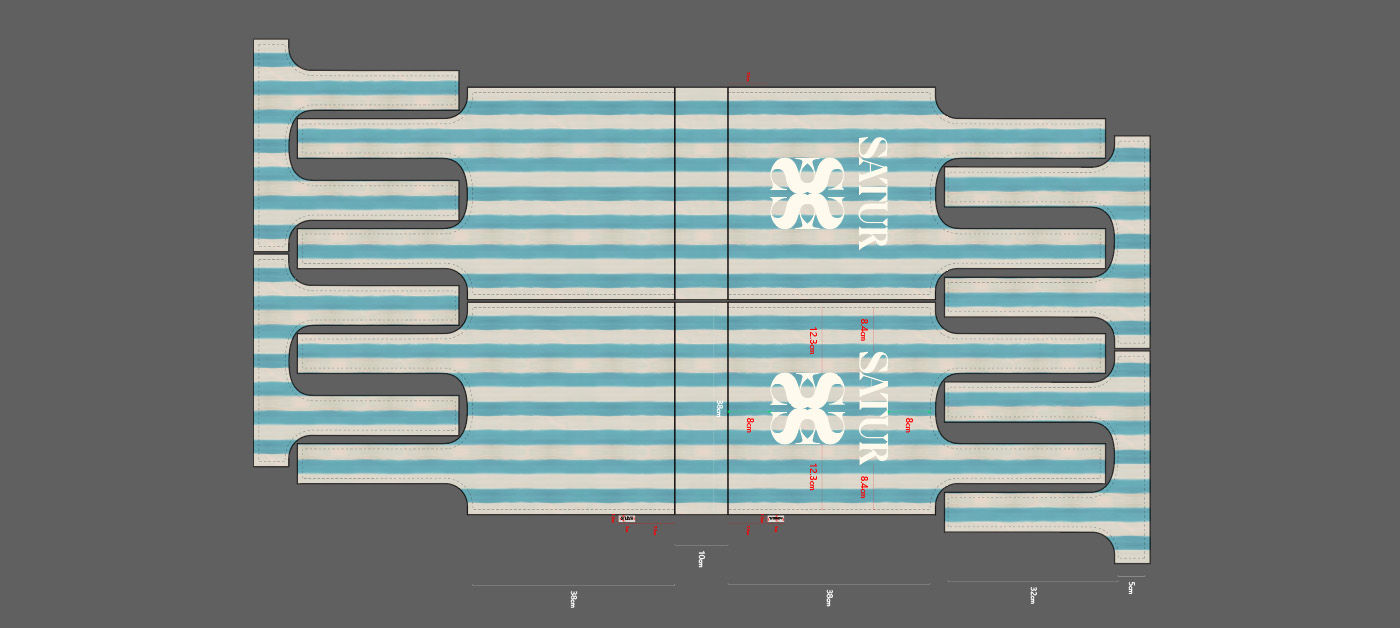

- Unconventional fabrics: Customized fabrics (D version 9101C + 2234) were required. The team arranged for two staff members to accompany the client to search the market on-site before finally finding suitable materials.

- Complex printing process: A combination of heat sublimation and screen printing was adopted, with extremely high color requirements. Three staff members accompanied the client to adjust colors for 4 days, testing more than 20 schemes and consuming dozens of meters of fabric to confirm the effect.

- Difficult sewing: The handle was designed with a double layer, which increased sewing time. Moreover, it was required that there should be no deformation after sewing and no misalignment between the two layers, placing strict demands on sewing precision.

- Special packaging requirements: Waist seals and plastic bags were needed, adding procedures to the packaging process.

- Tight delivery time: Within the 1-month delivery cycle, it was necessary to deal with multiple time-consuming links — multiple screen printings were required to avoid bottom exposure; waiting for screen printing to dry (often, after cutting pieces in the first half of the day, screen printing was done immediately, and even overnight work was carried out); long sewing time required overtime work; the initial sample needed to be rushed, and a chartered car was sent to the airport while the client was waiting. The client was able to catch the flight only after the punctual delivery; bulk goods needed to be shipped in batches to ensure timeliness.

- Strict price control: The client had strict requirements on prices, so accurate cost accounting was needed in all links of material procurement and processing.

Solutions

Material and process breakthrough: A special team was set up for docking, and dedicated personnel were arranged to accompany the client to solve fabric procurement problems. For the difficulty of printing colors, technical personnel were mobilized to cooperate with debugging throughout the process, recording the effect of each scheme until meeting the client's standards.

Production efficiency optimization: A phased production plan was formulated, with close connection between cutting, screen printing, and sewing links — shift work was adopted in the screen printing link, and overnight work was carried out to reduce drying waiting time; more staff were assigned to the sewing link and working hours were extended to ensure that complex processes such as double-layer handles were completed on time.

Emergency response mechanism: For the urgent need of samples, all links were coordinated for priority processing, and a special car was arranged to deliver them to the airport to ensure that the client could take the samples on the plane on time. In the bulk goods stage, the mode of batch production and batch shipment was adopted to reduce delivery pressure.

Refined cost control: Each item from material procurement to processing was accounted for. On the premise of ensuring quality, material usage was optimized and redundant processes were streamlined to ensure that the price met the client's expectations.

🚩About the Client

SATUR is a brand founded in Seoul in 2020 with the slogan "Give yourself a Saturday". It presents a modern style with a resort feel, reflecting the relaxed and peaceful atmosphere of Saturday.

Among them, T-shirts, Sublimation T-shirts, and customized canvas bags are important categories of SATUR.

🔗https://satur.co.kr/

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric printing enterprise integrating product R&D, design, production, and sales. It provides a full range of fabric printing products, including towels, golf towels, flags, advertising T-shirts, sports goods, fan scarves, hats, and other election peripherals.

With 31 years of production experience, its products are exported to the United States, Europe, East Asia, Africa, and the Middle East, and it has established long-term cooperative relationships with enterprises around the world. Equipped with more than 300 high-quality employees and 3 production bases (with a total area of 5,000 square meters, covering raw material centers, sewing centers, fully automatic printing centers, assembly centers, etc.), it can quickly respond to urgent order needs and provide efficient OEM/ODM services for clients.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

Business Director of Guangzhou Chuangrui International Trade Co., Ltd.

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap