Brand Story

Cultural and Creative Peripheral Demander of a Well-Known Condiment Brand

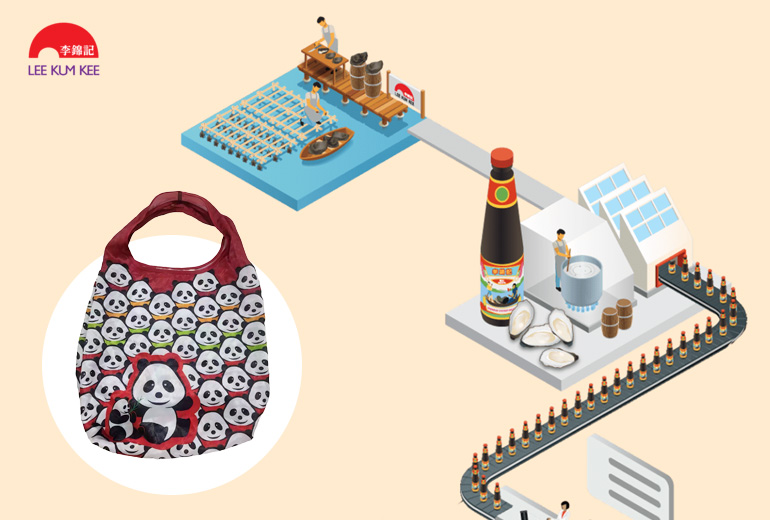

As a world-renowned condiment brand, Lee Kum Kee customized 35,000 panda shopping bags this time for brand event gifts and offline store promotion. Integrating "panda" elements and brand logos, the shopping bag is not only a practical shopping tool but also a carrier for brand culture communication, with high requirements for product uniqueness (special fabric + irregular design), quality (consistent with brand tone), and delivery efficiency.

Brand Goals

Convey Brand Culture with Custom Shopping Bags

Customize 35,000 panda shopping bags with both practicality and design sense, highlighting brand creativity through special fabric and irregular folding structure. To align with the brand event schedule, production must be completed in a short cycle, and strict quality inspection is required to ensure the product meets brand quality standards.

Challenges Faced

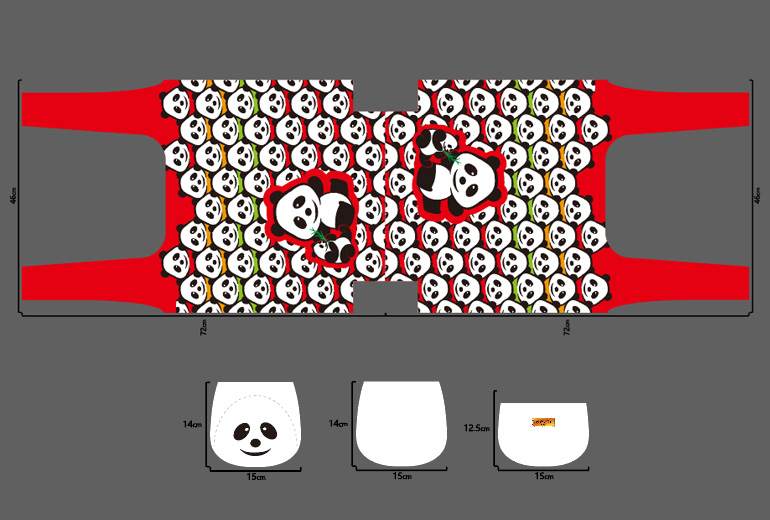

Irregular structure production: Folded into an irregular small bag, the cutting size must be precise (error controlled within 1mm). Sewing is prone to skew, and packaging must match the irregular structure to avoid deformation.

- Need for sampling iteration: Due to the special fabric and structure, the initial sample needs adjustments in printing effect and structural stability, requiring multiple optimizations.

- Urgent delivery pressure: The event time is fixed, with a short production cycle, requiring compression of the entire process time from sourcing to delivery.

- On-site inspection test: The client will conduct an on-site inspection in person, with strict requirements for fabric texture, printing precision, and structural firmness.

Solutions

Rapid response to special fabric: Cooperated with 5 high-quality fabric suppliers to collect 3 alternative unconventional fabrics within 48 hours, tested their printing color development effect and durability, selected the suitable fabric, and simultaneously started sampling.

Process optimization for irregular structure: For the irregular small bag design, formulated the process of "computerized cutting bed for precise cutting (error ≤0.5mm) + special sewing mold positioning" to solve the problem of sewing skew; designed an exclusive packaging mold to ensure stable shape after folding.

Solutions

Sampling and quality control enhancement: 3 samplings optimized "fabric printing parameters", "cutting size", and "sewing tension" respectively. A test report (including printing clarity, structural load-bearing, etc.) was generated after each sampling; before the client's on-site inspection, full inspection was completed according to simulated inspection standards to rectify potential problems in advance.

Urgent production scheduling: The production cycle was split into "2 days for sourcing and sampling + 5 days for mass production + 1 day for quality inspection and packaging". 2 production lines were activated for parallel production, and a dedicated person was assigned to track progress to ensure on-time delivery.

35,000 panda shopping bags were delivered as per the urgent deadline, with a 100% pass rate in the client's on-site inspection. The special fabric printing was clear, and the irregular structure was firm, becoming a popular peripheral in brand events. This cooperation confirmed Gahumi's response and execution capabilities in special customization needs, laying a foundation for subsequent cultural and creative peripheral cooperation.

🚩About the Client

Lee Kum Kee has been deeply engaged in the condiment industry for many years, with "quality first" as its core. Brand peripheral customization needs to reflect the tone of "coexistence of creativity and quality". When selecting suppliers, it focuses on "ability to solve special needs", "strict quality control", and "delivery reliability".

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric product enterprise integrating R&D, design, production, and sales, with 31 years of customization experience. Relying on rich supplier resources, process R&D capabilities, and a flexible production system, it can quickly respond to customization needs such as special fabrics and irregular structures. With services of "fast sourcing, accurate sampling, and strict quality control", it has become a trusted partner for brand cultural and creative products and event peripheral customization.

The Solution

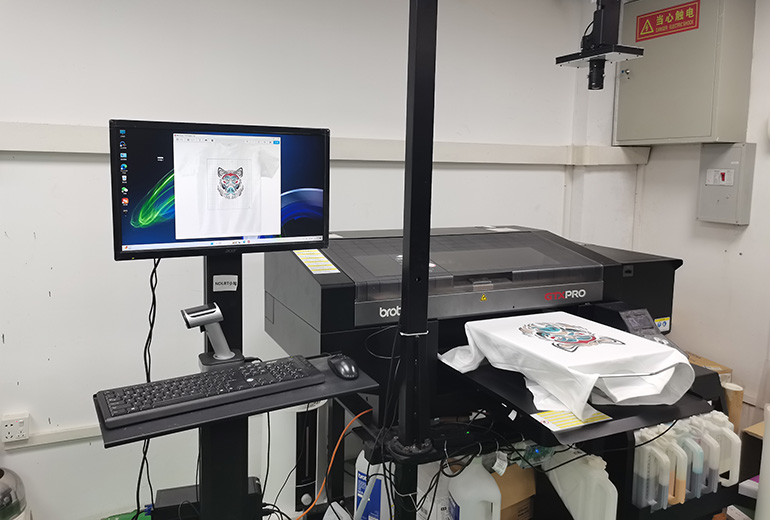

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

Customer Testimonial

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap