Brand Story

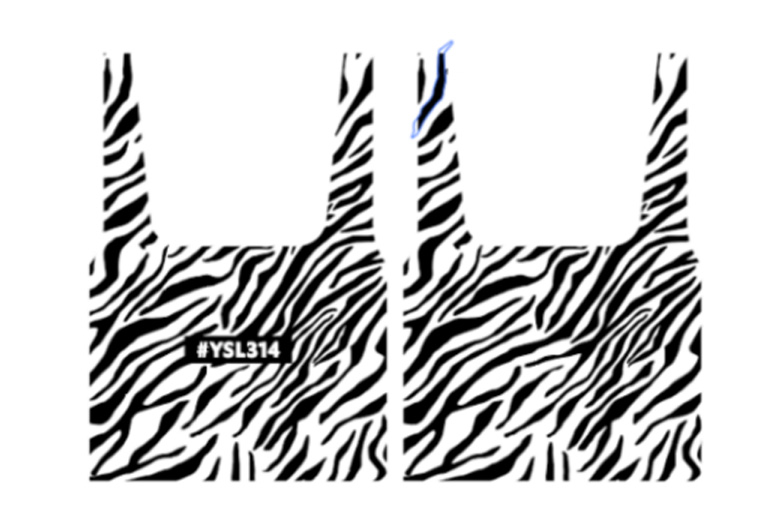

As a well-known beauty brand, YSL uses points redemption as a key method to maintain user stickiness. The customized canvas tote bags for this project, serving as points redemption gifts, not only need to fulfill the function of "rewarding users" but also convey a high-end texture through brand elements. The brand logo and color scheme on the bag must strictly adhere to the brand's visual system, making it a mobile brand display carrier.

Brand Goals

YSL aimed to enhance the attractiveness of points redemption and strengthen users' favorability toward the brand with 50,000 customized canvas tote bags. It required the tote bags to meet high-end standards in material texture, color reproduction (consistent with the brand's classic colors), and logo printing precision. Additionally, the bags needed to be delivered before the launch of the points redemption activity to ensure the gifts were available on time.

Challenges Faced

High requirements for brand visual reproduction: YSL's brand colors (such as classic gold and black) needed precise matching, and the logo printing had to be clear without burrs to avoid color deviations that could harm the brand image.

Difficulty in controlling consistency in mass quality: 50,000 canvas tote bags required uniform material feel, sewing craftsmanship, and printing effects. Any batch differences might affect the user experience.

Strong binding between delivery and the activity: The points redemption activity had a fixed schedule, so the tote bags needed to be warehoused in advance and prepared for gift listing, leaving no buffer space in the delivery cycle.

Material adaptability testing: As a daily-used gift, the canvas material needed to be wear-resistant and of good texture, while ensuring that printed patterns did not easily fall off.

Solutions

Precise implementation of brand visuals: A dedicated visual docking team was established. First, YSL's brand color cards and standard logo files were obtained. Ink ratios were determined through 3 color-matching tests, and high-precision screen printing technology was used to ensure clear logo edges. Finally, it passed the brand's visual review.

Standardized control of mass production: Unified production standards were formulated (including fabric batch screening, sewing stitch distance requirements, and printing position error ranges). For every 1,000 units produced, 20 were randomly selected for quality inspection to ensure consistent quality across all 50,000 units.

Production and delivery rhythm planning: The production process was split into "fabric procurement - printing - sewing - quality inspection - packaging," with seamless connection between each link. Two production lines were launched to operate in parallel, achieving a daily output of 8,000 units. A 3-day buffer period was reserved for final quality inspection and warehousing.

Material selection and process adaptation: 32-count dense canvas was chosen (balancing texture and durability). Wear resistance and wash resistance tests were conducted in advance (simulating user scenarios) to ensure printed patterns showed no obvious peeling after 10 washes.

🚩About the Customer

YSL is a world-renowned beauty brand known for its high-end positioning and fashionable design. Points redemption is one of its core user operation methods, with strict requirements for the brand fit, quality, and delivery timeliness of redemption gifts.

🔗https://www.yslbeautyus.com/

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric printing enterprise integrating product research and development, design, production, and sales. Its products include canvas tote bags, towels, and advertising T-shirts. With 31 years of production experience, it has accumulated profound expertise in material selection, color matching, and production processes, and established a sound quality management and supply chain system. It has over 300 employees and 3 production bases (with a total area of 5,000 square meters), enabling it to efficiently respond to mass customization needs while balancing cost control and service quality, providing customers with full-process services from sampling to delivery.

👏Summary

The success of this order stemmed from Gahumi's accurate response to the needs of "brand customization + mass delivery." It solved the problems of color and logo reproduction through standardized brand visual implementation, and ensured consistent quality and on-time delivery of 50,000 units through standardized production and parallel production scheduling. This not only demonstrated its technical accumulation in materials and processes but also verified its ability in efficient response and quality control, perfectly matching the needs of points redemption gift scenarios.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

YSL Brand User Operations Director

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap